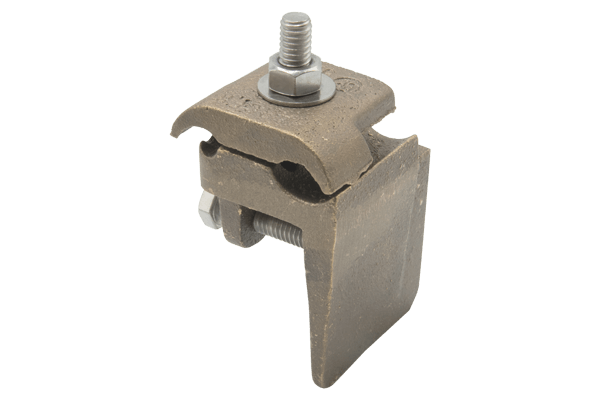

Secondary Flange Bonding Plates

Product Information

Product Variations

| Product No. | Material | Box Qty. | Approx. Box Wt. (lbs.) | Documents | |

|---|---|---|---|---|---|

| AFBP | Aluminum | 10 | 4 | ||

| CFBP | Bronze | 10 | 11.25 | ||

| TCFBP | Tinned Bronze | 10 | 11.25 |

• Provides over 4 square inches of bonding surface.

• Large cable connector offers 1-1/2" of contact between the bonding plate and the cable.

• Larger cable channel accommodates conductors up to 500 MCM.

• "TP-Tamper Proof" - Ideal in high theft areas when bonding to steel I-beams up to 1" thick.

• Recommended installation tool - 1/2" socket wrench, end wrench, or nut driver.

• A bonding plate shall have a minimum thickness of not less than 3/32 inch (2.4 mm). The thickness shall not be less than 5/16 inch (7.9 mm) for bosses for screw threads.

• A Class I bonding plate shall have a minimum surface contact area of 3 square inches (19.4 cm2).

• A Class II bonding plate shall comply with the material and dimensional requirements for Class I bonding plates.

• A bonding plate for utilizing the steel framework as a conductor shall have a surface contact area of not less than 8 square inches (52 cm2).